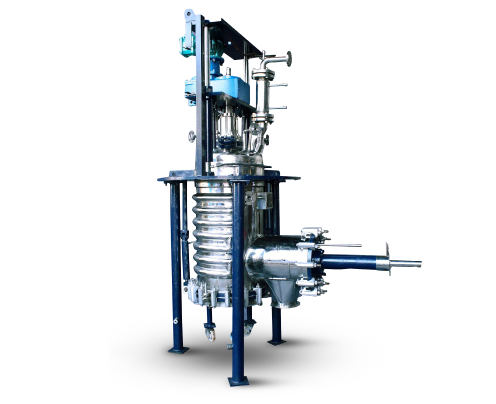

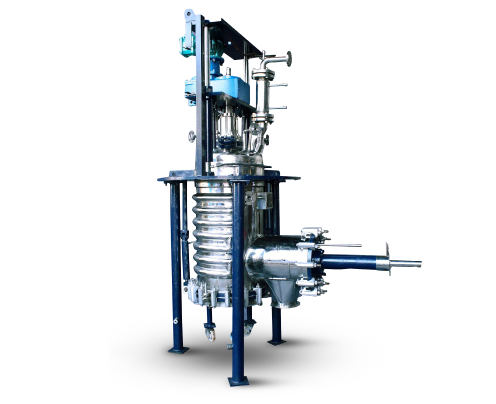

Agitated Nutsche Filter Dryers (ANFD)

The Agitated Nutsche Filter Dryer (ANFD) is an advanced piece of equipment designed for efficient solid-liquid separation, filtration, and drying—all in one system. With its innovative design, the agitated nutsche filter minimizes manual intervention while maximizing solvent recovery and drying efficiency, making it the perfect solution for industries requiring controlled agitated filter and drying processes.

product specification

product specification

Capacity

100 LITERS TO 20 KL

Material of Construction

(MOC: SS 316/SS 304/HC-22/HC-276/DUPLEX/MS/CS/FRV Lining/Tefzel Lining)

Operation

Suitable for pressure or vacuum operation

Dimensions

Available in standard and customizable sizes

Agitator

Vertical and rotational movements for smooth filtration and drying

Heating System

Indirect heating through jacket or coils

Filter Media

Perforated plate with cloth/tiles based on application

Control System

Fully automated via PLC for precision operations

Compliance

Available with special construction for sterile environments (pharmaceutical grade)

Applications of product

The Agitated Nutsche Filter Dryer finds use in various industries for solid-liquid separation, washing, and drying in a single system. Common applications include:

Pharmaceuticals

For batch drying of sensitive compounds after filtration using the agitated nutsche filter.

Chemical Production

Efficient for filtering and drying chemicals in a controlled environment with the agitated filter dryer.

Dye and Pigment Manufacturing

Perfect for separating dyes and pigments from liquid media using the nutsche filter technology.

features of product

Multi-Functional

Combines filtration, washing, and drying in a single enclosed unit.

Automated Operations

PLC-controlled processes ensure precision and reduce manual labor.

Efficient Washing

Re-slurrying feature allows thorough washing of the cake, improving product quality.

High Solvent Recovery

Maximum recovery of solvents through pressure/vacuum operations.

Safe and Clean

Enclosed system prevents environmental contamination and exposure to hazardous fumes.

UNIFAB ultra

Advantages of product

The design eliminates the risk of spills, significantly reducing potential fire or explosion hazards.The design eliminates the risk of spills, significantly reducing potential fire or explosion hazards.

Complete Process in One Equipment

Perform multiple functions—filtration, washing, and drying—without transferring material between systems.

High-Quality Construction

Built with durable materials like SS304, SS316, and Hastelloy for long-term reliability.

Improved Productivity

Reduce processing times by completing all steps in one efficient system.

Energy-Efficient Drying

Indirect heating systems ensure energy-efficient drying of the product.

why to choose

UNIFAB

At UNIFAB ULTRA, we prioritize precision engineering, durability, and innovation. Our Agitated Nutsche Filter Dryers are designed with the highest standards in mind, ensuring exceptional performance in every application. With over 15 years of experience, our manufacturing processes guarantee the highest levels of quality control, safety, and operational efficiency.

Request a quote

Ready to elevate your drying and filtration process with the Agitated Nutsche Filter Dryer (ANFD) from UNIFAB ULTRA? Contact us today for a tailored solution and see how our advanced equipment can optimize your production workflow.

testimonials

Ut enim ad minim veniam, quis nostrudexercitation ullamco laboris nisi ut aliquip ex ea commodo consequat aute irure sint amet occaecat cupidatat non proident”

Ut enim ad minim veniam, quis nostrudexercitation ullamco laboris nisi ut aliquip ex ea commodo consequat aute irure sint amet occaecat cupidatat non proident”

Ut enim ad minim veniam, quis nostrudexercitation ullamco laboris nisi ut aliquip ex ea commodo consequat aute irure sint amet occaecat cupidatat non proident”

Ut enim ad minim veniam, quis nostrudexercitation ullamco laboris nisi ut aliquip ex ea commodo consequat aute irure sint amet occaecat cupidatat non proident”

FAQ's

Frequently Asked Questions

What materials can the ANFD handle?

The agitated nutsche filter dryers can handle a variety of materials, including sensitive pharmaceuticals, chemicals, and wastewater solids.

Is the system fully automated?

Yes, the agitated filter dryer is controlled through a PLC system, making the entire process automated and easy to operate.

Can this equipment be customized for sterile applications?

Yes, we offer special constructions for sterile environments, meeting high standards of particulate purity for pharmaceutical uses.