Pilot Models

how it works

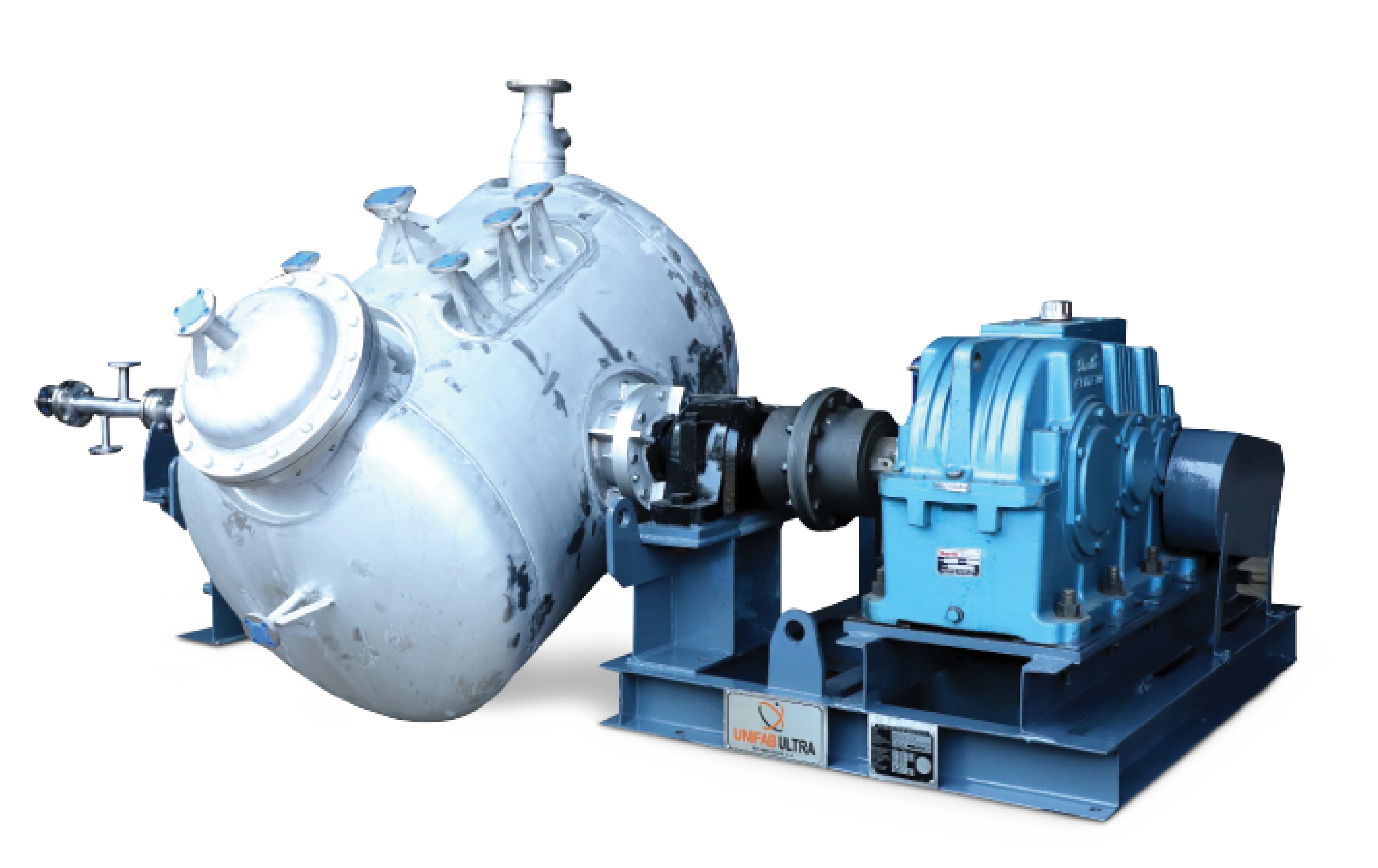

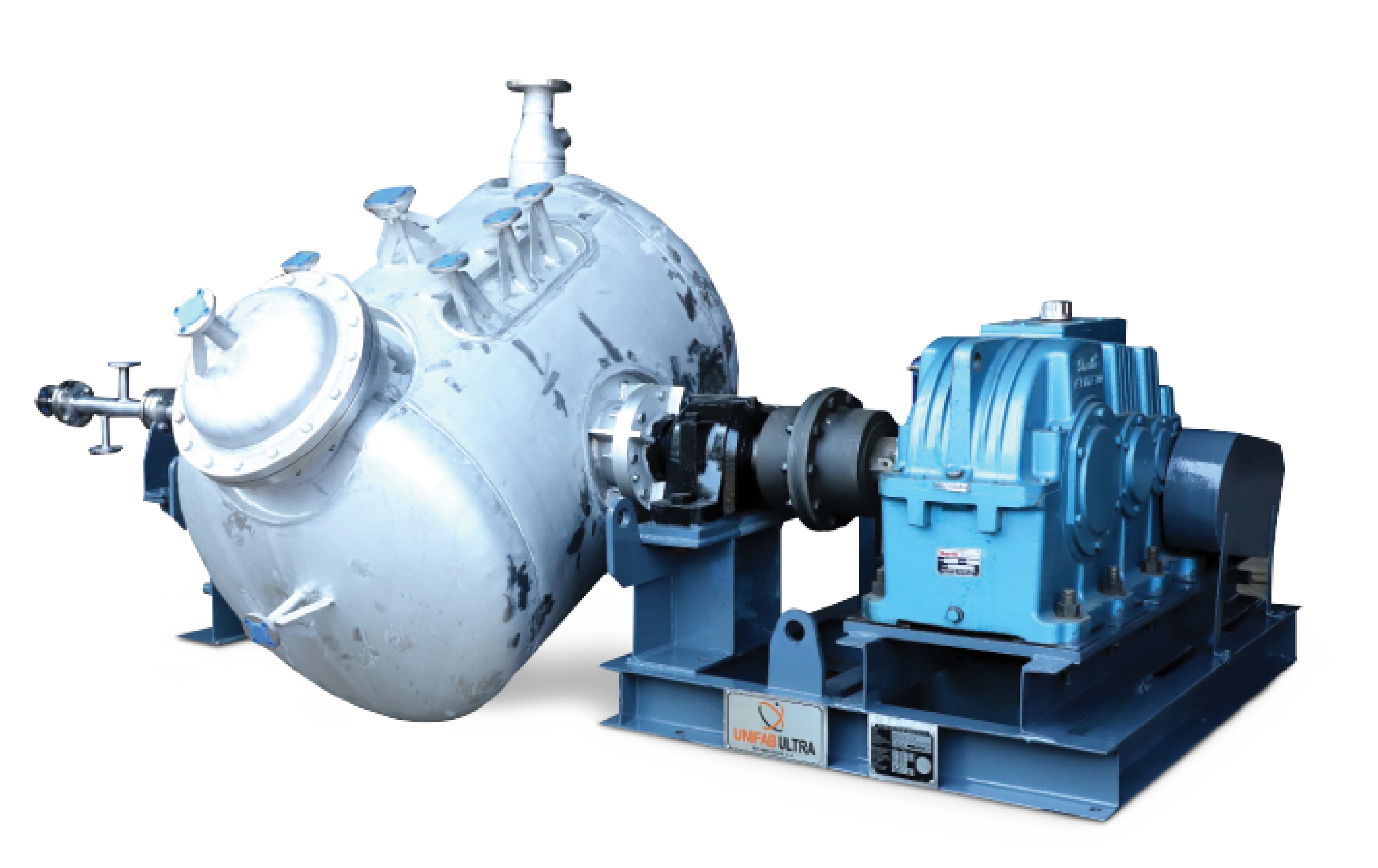

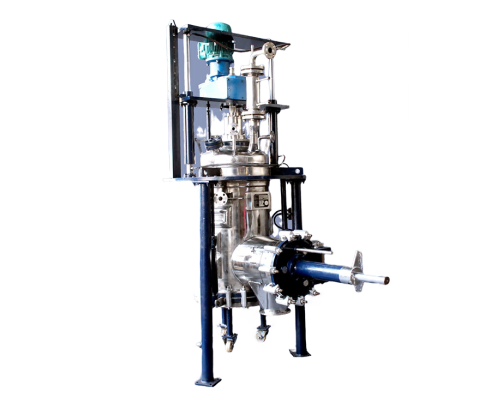

The filtration process begins when the slurry enters the filter from the vessel, flowing into the top compartment. Here, the filtrate is directed into the lower chamber, while solids are deposited on the filtering media in a uniform cake-like structure. The specially designed agitator maintains the slurry’s motion, ensuring maximum filtrate extraction and sealing any cracks that may form in the cake.

As filtration progresses, the agitator uniformly compresses the cake to extract excess moisture. For additional washing, a wash liquor can be introduced to re-slurry the cake, guaranteeing thorough cleaning of every particle. Once the cake is adequately washed, it is automatically discharged through a side valve, all controlled via a user-friendly panel for smooth and efficient operations.

product specification

product specification

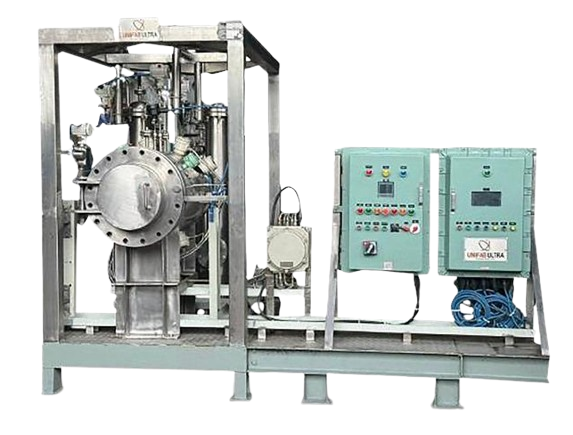

Modular Design for easy transport and handling

Pre-piped & Pre-wired for quick installation

Customizable Size and configuration based on client needs

Trial Support for customer material testing

Portable units for easy site relocation

Applications of product

Research and Development (R&D)

Material Testing

Process Optimization

Technology Demonstrations

features of product

UNIFAB ultra

Advantages of product

Rapid Testing

Cost-Effective

Customizable

Efficient Transportation

Proven Technology

why to choose

UNIFAB

Request a quote

Ready to transform your filtration process with the Agitated Nutsche Filter from UNIFAB ULTRA? Contact us today for a customized quote and discover how our equipment can enhance your operational efficiency.