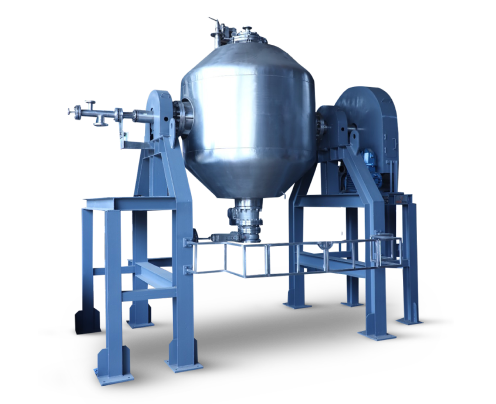

Rotary Double Cone Vacuum Dryer (RCVD)

The Rotary Double Cone Vacuum Dryer is a highly efficient solution designed to dry heat-sensitive materials under vacuum conditions. Ideal for delicate products, it ensures uniform drying by gently tumbling the material within the cone, minimizing the risk of product degradation. This dryer offers excellent drying results while preserving the quality and purity of the product.

how it works

The filtration process begins when the slurry enters the filter from the vessel, flowing into the top compartment. Here, the filtrate is directed into the lower chamber, while solids are deposited on the filtering media in a uniform cake-like structure. The specially designed agitator maintains the slurry’s motion, ensuring maximum filtrate extraction and sealing any cracks that may form in the cake.

As filtration progresses, the agitator uniformly compresses the cake to extract excess moisture. For additional washing, a wash liquor can be introduced to re-slurry the cake, guaranteeing thorough cleaning of every particle. Once the cake is adequately washed, it is automatically discharged through a side valve, all controlled via a user-friendly panel for smooth and efficient operations.

Capacity Ranges

CAPACITY

200 Liters to 8 KL

(MOC)

SS 316/SS 304/, Hastelloy C-22/Hastelloy C-276, Duplex Stainless Steel, Tefzel Lining, MS/CS

Industries

Chemical

Agro-Chemical

Pesticides

Paints & Pigments

Bulk Drugs/Pharmaceuticals(API)

product specification

Capacity

200 LITERS TO 8 KL

Material of constructions (MOC)

SS 316/SS 304/HC-22/HC-276/DUPLEX/MS/CS/ Tefzel Lining)

Dimensions

Customizable based on application requirements

Weight

Varies depending on design and capacity

Operation

Vacuum drying with low-temperature capabilities

Design Features

Designed for gentle tumbling and uniform heat distribution

Applications of product

The Rotary Double Cone Vacuum Dryer is widely used in industries that require precise drying of sensitive materials. Applications include:

This dryer is especially suited for heat-sensitive, toxic, and hygroscopic materials, providing safe and efficient drying without contamination.

Pharmaceuticals

Drying active pharmaceutical ingredients (APIs), excipients, and other sensitive materials.

Chemicals

Drying specialty chemicals and catalysts under controlled temperatures.

Food Industry

Ideal for drying food ingredients while retaining their nutritional properties.

Fine chemicals and specialty compounds

Efficient drying of materials that require precise temperature control.

features of product

Dual Cone Design

Ensures uniform tumbling and even drying of the material.

Vacuum Drying

Reduces drying time while preserving product integrity.

Gentle Operation

Ideal for fragile or sensitive materials that require careful handling.

Efficient Heat Transfer

The dryer is equipped with a heating jacket that circulates hot fluid to provide the necessary heat for drying.

Controlled Environment

Reduces oxidation and contamination risks through vacuum operation.

UNIFAB ultra

Advantages of product

Uniform Drying

The Roto Cone Dryer provides uniform heat distribution by continuously rotating the material in a vacuum, ensuring that all particles are dried evenly. This is particularly important for heat-sensitive materials that need gentle drying to maintain quality.

Gentle on Heat-Sensitive Materials

The RCD operates under vacuum conditions, which allows it to dry materials at lower temperatures compared to conventional dryers. This makes it ideal for heat-sensitive substances like pharmaceuticals, food products, or bioactive compounds that could degrade or lose potency at high temperatures.

Efficient Drying Process

Due to its rotating cone design, the dryer ensures continuous mixing and exposure of materials to the drying environment, improving heat and mass transfer efficiency, which leads to faster and more efficient drying.

Solvent Recovery

Since the Roto Cone Dryer often operates under a vacuum, it allows for the recovery of solvents (if used during processing), making it an environmentally friendly and cost-effective choice for processes that involve volatile solvents.

Reduced Dust Generation

Because of the enclosed nature of the drying process and the vacuum operation, there is less dust and particle loss in comparison to traditional dryers. This is particularly important in industries where airborne particles need to be minimized for safety and cleanliness.

Compact and Space-Saving

The design of the Roto Cone Dryer is often more compact than traditional drying equipment, making it suitable for facilities with limited space. This helps maximize floor area utilization.

Easy Operation and Maintenance

The Roto Cone Dryer is relatively easy to operate and maintain, with a straightforward loading and unloading mechanism. The design is typically user-friendly, reducing the risk of human error during operation.

Low Energy Consumption

The RCD’s efficiency in drying under a vacuum lead to lower energy consumption compared to other conventional dryers, which require more energy to heat the air and evaporate moisture.

Versatility

Roto Cone Dryers are versatile and can be used for drying powders, granules, slurries, or pastes. This versatility makes it suitable for a wide range of industries, including pharmaceuticals, chemicals, food processing, and more.

Improved Product Quality

The gentle drying process of the Roto Cone Dryer helps preserve the molecular structure and integrity of sensitive materials, which is important in maintaining the final product’s quality, especially in pharmaceuticals and food processing.

In summary, the Roto Cone Dryer provides several advantages like uniform drying, energy efficiency, gentle handling of heat-sensitive materials, and solvent recovery, making it a popular choice for industries that require precise and efficient drying solutions.

why to choose

UNIFAB

At UNIFAB ULTRA, we are dedicated to providing industry-leading drying solutions. With years of expertise in the design and manufacturing of high-quality equipment like the Rotary Cone Vacuum Dryer, we ensure that each product meets stringent quality standards. Our commitment to innovation, customer satisfaction, and safety sets us apart from competitors.

Request a quote

Ready to revolutionize your drying process with the Rotary Vacuum Paddle Dryer from UNIFAB ULTRA? Contact us today for a customized quote and see how our advanced RVPD dryer can improve your efficiency and product quality!

testimonials

We recently installed Unifab ULTRA's ANFD unit and were impressed with the build quality and performance. It’s been a game-changer for our drying process.

Rahul Mehta

The RVPD we sourced from Unifab has significantly improved our solvent recovery efficiency. A reliable and well-engineered system!

Neha Sharma

Unifab ULTRA’s ANF has exceeded our expectations in both quality and performance. Their after-sales support is also commendable.

Amit Kulkarni

We’ve been using the RCVD from Unifab for over a year. It runs flawlessly and has helped us maintain consistency in our formulations.

Pooja Desai

What sets Unifab ULTRA apart is their attention to detail. The ANFD we purchased works seamlessly and is extremely easy to maintain.

Vikram Sinha

Our team appreciates the robust design of Unifab's RVPD. It’s a compact unit but delivers outstanding vacuum performance.

Sneha Patil

We replaced our old setup with Unifab’s ANF system. The results were immediate—higher throughput and better filtration.

Karan Malhotra

The RCVD system from Unifab ULTRA is well-constructed and offers consistent batch processing. We're highly satisfied with its durability.

Meera Iyer

Unifab’s ANFD has brought noticeable improvement in our drying cycles. Great efficiency and smooth integration with our existing line.

Ritesh Nair

Working with Unifab ULTRA was a great experience. Their RVPD unit was delivered on time, installed quickly, and performs exceptionally well.

Anjali Rao

Frequently Asked Questions

What is the rotary cone vacuum dryer working principle?

The Rotary Cone Vacuum Dryer works by rotating the cone-shaped vessel under vacuum, which reduces the boiling point of the solvents. The material inside is gently tumbled for uniform heat exposure, ensuring efficient drying without degrading sensitive compounds.

What materials can be dried using this dryer?

The Rotary Double Cone Vacuum Dryer is ideal for heat-sensitive, toxic, and hygroscopic materials, commonly used in pharmaceutical, chemical, and food industries.

Can the equipment be customized?

Yes, we offer customized rotary double cone vacuum dryers based on your specific industry requirements and material needs.