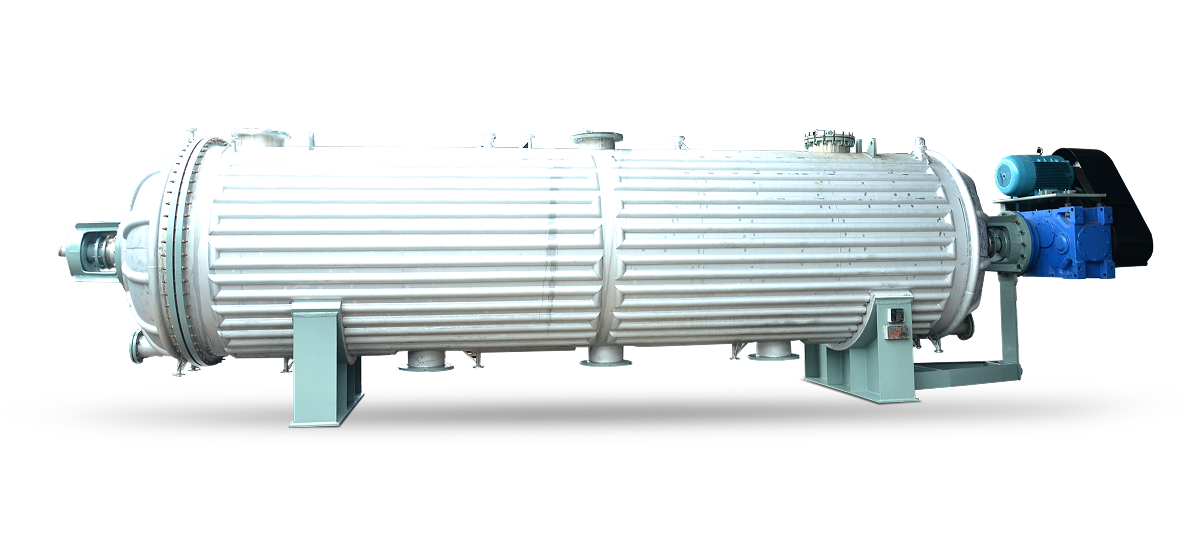

Rotary Vacuum Paddle Dryer (RVPD)

The Rotary Vacuum Paddle Dryer (RVPD) is a cutting-edge drying solution designed to efficiently dry materials under vacuum conditions. Ideal for industries where low-temperature drying is essential, this vacuum paddle dryer ensures uniform drying while preserving the quality of heat-sensitive materials. The rotary paddle dryer operates with a unique design that optimizes the drying process, making it the preferred choice for industries such as pharmaceuticals, chemicals, and food processing.

Capacity Ranges

CHARGING CAPACITY

40% to 60% of Gross Capacity depending on the nature of the products

(MOC)

SS 316/SS 304/Hastelloy C-22/Hastelloy C-276/MS/CS/ Duplex Stainless Steel

CAPACITY

150 Liters to 30 KL

GROSS CAPACITY

30,000 ltrs

3 KL RVPD, Direct Drive available in Ex-Stock

Industries

Chemical

Agro-Chemical

Pesticides

Paints & Pigments

Bulk Drugs/Pharmaceuticals(API)

product specification

product specification

Design

Cylindrical body with a central rotary shaft and paddle agitators.

Capacity

150 LITERS TO 30 KL

Material of Construction

(MOC: SS 316/SS 304/HC-22/HC-276/DUPLEX/MS/CS)

Temperature Range

Suitable for low-temperature drying under vacuum.

Power

Energy-efficient motor with variable speed control for the rotary paddles.

Pressure

Vacuum operation up to (-) 760 mm Hg.

Applications of product

Pharmaceuticals

Drying active pharmaceutical ingredients (APIs), excipients & other sensitive materials.

Chemicals

Drying specialty chemicals and catalysts under controlled temperatures.

Food Industry

Ideal for drying food ingredients while retaining their nutritional properties.

Polymers and Resins

Efficient drying of materials that require precise temperature control.

Applications of product

The Rotary Vacuum Paddle Dryer is used across a range of industries, including:

Pharmaceuticals

Drying active pharmaceutical ingredients (APIs), excipients, and other sensitive materials.

Chemicals

Drying specialty chemicals and catalysts under controlled temperatures.

Food Industry

Ideal for drying food ingredients while retaining their nutritional properties.

Polymers and Resins

Efficient drying of materials that require precise temperature control.

features of product

Vacuum Operation

Ensures efficient drying at lower temperatures, preventing degradation of sensitive materials.

Paddle Agitators

Provide uniform mixing and prevent material buildup on the dryer walls.

Rotary Design

The continuous rotation of the central shaft ensures even heat distribution and quick drying.

Energy Efficiency

Low energy consumption with optimized heat transfer.

Safety Features

Incorporates safety measures to prevent overheating and ensure safe operation under vacuum conditions.

Controllable Environment

The ability to control temperature and vacuum levels provides precise drying conditions, reducing the risk of product degradation.

Easy Maintenance

Designed for easy access to internal components for cleaning and maintenance.

UNIFAB ultra

Advantages of product

The design eliminates the risk of spills, significantly reducing potential fire or explosion hazards.The design eliminates the risk of spills, significantly reducing potential fire or explosion hazards.

Fast Drying Times

RVPD enables rapid drying of materials, reducing processing time and increasing efficiency.

Low-Temperature Drying

The vacuum environment allows for low-temperature drying, preserving heat-sensitive materials and preventing degradation.

Uniform Drying

The rotary paddle design ensures uniform heat transfer and drying, resulting in consistent product quality.

High-Efficiency

RVPD can achieve high drying efficiencies, reducing energy consumption and costs.

Flexibility

RVPD can handle a wide range of materials, including slurries, pastes, and powders.

Easy Cleaning and Maintenance

The design of RVPD allows for easy cleaning and maintenance, reducing downtime and improving overall efficiency.

Scalability

RVPD is available in various sizes, from laboratory-scale to large-scale production units, making it suitable for a wide range of applications.

Reduced Product Loss

The vacuum environment and rotary paddle design minimize product loss and waste.

Improved Product Quality

RVPD helps preserve the physical and chemical properties of materials, resulting in high-quality products.

Cost-Effective

RVPD can help reduce overall processing costs by minimizing energy consumption, reducing waste, and increasing efficiency

UNIFAB ultra

Advantages of product

Durability

Built with high-grade stainless steel for long-lasting performance.

Superior Performance

The rotary design enhances drying efficiency, saving time and energy.

Customizable

The Rotary Vacuum Paddle Dryer design can be customized to meet specific industry needs.

Multi-Purpose

Handles various drying processes, including filtration, washing, and drying in one

why to choose

UNIFAB

At UNIFAB ULTRA, we pride ourselves on delivering top-notch engineering solutions that meet industry demands. Our RVPD dryers are designed with precision to ensure maximum efficiency, energy savings, and safety. With a legacy of excellence and a commitment to innovation, we offer unmatched quality in every product we manufacture.

Request a quote

Ready to transform your filtration process with the Agitated Nutsche Filter from UNIFAB ULTRA? Contact us today for a customized quote and discover how our equipment can enhance your operational efficiency.

Costumer Review

testimonials

We recently installed Unifab ULTRA's ANFD unit and were impressed with the build quality and performance. It’s been a game-changer for our drying process.

Rahul Mehta

The RVPD we sourced from Unifab has significantly improved our solvent recovery efficiency. A reliable and well-engineered system!

Neha Sharma

Unifab ULTRA’s ANF has exceeded our expectations in both quality and performance. Their after-sales support is also commendable.

Amit Kulkarni

We’ve been using the RCVD from Unifab for over a year. It runs flawlessly and has helped us maintain consistency in our formulations.

Pooja Desai

What sets Unifab ULTRA apart is their attention to detail. The ANFD we purchased works seamlessly and is extremely easy to maintain.

Vikram Sinha

Our team appreciates the robust design of Unifab's RVPD. It’s a compact unit but delivers outstanding vacuum performance.

Sneha Patil

We replaced our old setup with Unifab’s ANF system. The results were immediate—higher throughput and better filtration.

Karan Malhotra

The RCVD system from Unifab ULTRA is well-constructed and offers consistent batch processing. We're highly satisfied with its durability.

Meera Iyer

Unifab’s ANFD has brought noticeable improvement in our drying cycles. Great efficiency and smooth integration with our existing line.

Ritesh Nair

Working with Unifab ULTRA was a great experience. Their RVPD unit was delivered on time, installed quickly, and performs exceptionally well.

Anjali Rao

FAQ's

Frequently Asked Questions

What is the working principle of a Rotary Vacuum Paddle Dryer?

The Rotary Vacuum Paddle Dryer working principle involves the material being continuously agitated by paddles while being heated under vacuum conditions, which removes moisture efficiently without damaging the material.

What industries use the RVPD dryer?

The RVPD dryer is widely used in pharmaceuticals, chemicals, food processing, and polymer industries for drying sensitive materials under controlled conditions.

Is the Rotary Vacuum Paddle Dryer customizable?

Yes, UNIFAB ULTRA offers customized designs to meet the specific needs of different industries.